| Stranded Aluminum Armored FO GYTA53 2~288 Core (LX2027) | ||||||

| Configuration & Physical characters | ||||||

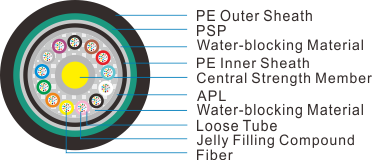

| The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core. Then the cable core is covered with a thin polyethylene (PE) inner sheath, which is filled with jelly to protect it from water ingress. After a corrugated steel tape armor is applied, the cable is completed with a PE outer sheath. | | |||||

| Product Specification | ||||||

| Cable Type | Fiber Count | Cable Diameter(mm) | Cable Weight(kg/km) | Tensile Strength | Crush Resistance | Bending Radius |

| Long/Short Term | Long/Short Term | Static/ Dynamic | ||||

| N | N/100mm | mm | ||||

| GYFTA53 | 2~6 | 13.1 | 176 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 8~12 | 13.1 | 175 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 14~18 | 13.1 | 174 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 20~24 | 13.1 | 174 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 26~30 | 13.1 | 173 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 32~36 | 13.1 | 172 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 38~48 | 13.5 | 183 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 50~60 | 13.5 | 182 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 62~72 | 13.7 | 184 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 74~84 | 14.1 | 196 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 86~96 | 14.9 | 215 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 98~108 | 15.6 | 233 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 110~120 | 16.3 | 254 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 122~132 | 17 | 273 | 1000/3000 | 1000/3000 | 10D/20D |

| GYFTA53 | 134~144 | 17.7 | 294 | 1000/3000 | 1000/3000 | 10D/20D |

| Temperature Range | ||||||

| Working | -40℃~+70℃ | |||||

| Storage/Transportation | -40℃~+70℃ | |||||

| Installation | -20℃~+60℃ | |||||

| Product Features & Application | ||||||

| Characteristics: | ||||||

| 1. Good mechanical and temperature performance | ||||||

| 2. High strength loose tube that is hydrolysis resistant | ||||||

| 3. Special tube filling compound ensure a critical protection of fiber | ||||||

| 4. Crush resistance and flexibility | ||||||

| The following measures are taken to ensure the cable watertight: | ||||||

| - Single Fiber Reinforced Plastic as the central strength member | ||||||

| - Loose tube filling compound | ||||||

| - 100% cable core filling | ||||||

| - APL moisture barrier | ||||||

| - PSP enhancing moisture-proof | ||||||

| - Water-blocking material | ||||||

| Standards: | ||||||

| GYFTA53 cable complies with Standard YD/T 901-2001as well as IEC 60794-1. | ||||||

| Fiber Details | ||||||

| Fiber type | G.652D | G655 | G657A.2 | OM2 | OM3 | |

| MFD @1310nm | 9.2±0.4μm | 1550nm: 9.6±0.5μm | 8.8±0.4μm | 50±2.5um | 50±2.5um | |

| OD of Cladding | 128.0±0.7μm | 125.0±0.7μm | 125.0±0.7μm | 125±1.0um | 125±2.0um | |

| Concentricity error | ≤0.5μm | ≤0.6μm | ≤0.5μm | ≤1.5um | ≤1.5um | |

| Non-circularity of cladding | ≤ 0.7% | ≤ 1.0% | ≤ 0.7% | ≤ 2.0% | ≤ 2.0% | |

| Cutoff wavelength | Λcc ≤1260 nm | Λcc ≤1450 nm | Λcc ≤1260 nm |

| | |

| Attenuation coefficient | ||||||

| 1310nm | ≤0.34dB/km | 1550nm : ≤0.22 dB/km | ≤0.35 dB/km | 850nm: ≤ 2.5dB/km | 850nm: ≤ 2.5dB/km | |

| 1550nm | ≤0.20 dB/km | 1625nm: ≤0.24 dB/km | ≤0.22 dB/km | 1300nm: ≤ 0.7dB/km | 1300nm: ≤ 0.7dB/km | |

| Dispersion coefficient | 1285-1340nm≤-3.0 ~ 3.0 ps/nm².km | 1530-1565nm≤2.0-6.0ps/nm².km |

|

|

| |

| 1550nm≤18ps/nm².km | 1565-1625nm≤4.5-11.2ps/nm².km |

|

|

| ||

| Zero-dispersion wavelength | 1312±10 nm | ≤1520nm | 1300nm-1324nm | 1295-1320 nm | 1295-1320 nm | |

| Zero-dispersion point slope | ≤0.092ps/nm2.km | ≤0.084ps/nm2.km | ≤0.092ps/nm2.km | 1300-1320nm: ≤ 0.11 ps/(nm2.km) | ≤0.11 ps/(nm2.km) | |

| PMDQ | PMD Q*≤0.2ps/km1/2 | PMD Q*≤0.2ps/km1/2 | PMD Q*≤0.2ps/km1/2 |

|

| |

| OD of coating layer | 245±5μm | 245±7μm | 245±5μm | 245±10um | 245±10um | |

| Screen tension | 100kpsi(0.7Gpa) | 100kpsi(0.7Gpa) | 0.69MPa | 100kpsi 0.7GPa | 100kpsi 0.7GPa | |

| PACKAGE AND MARK | ||||||

| 4.1 PACKAGE: Not allowed two length units of cable in one drum, two ends should be sealed,. Two ends should be packed inside drum. | ||||||

| 4.2 MARK: length, brand drum mark: manufacturer, cable category, No. of drum, length, GW. direction of rotation, manufacturing date. | ||||||

| 4.3 Package Length: by order | ||||||

LASUN

LASUN