| Non - Metal Strengthening Aluminum Armored FO GYFTA 2~288 Core (LX2025) | ||||||

| Configuration & Physical characters | ||||||

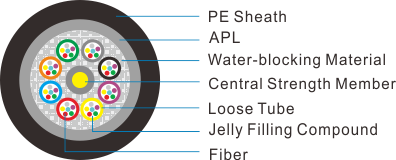

| The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. Waterproof filling compound filled into whole cable core, an Aluminum Polyethylene Laminate (APL) moisture barrier applied around the cable core and finally PE sheath completed over APL as outer protection. | | |||||

| Product Specification | ||||||

| Cable Type | Fiber Count | Cable Diameter(mm) | Cable Weight(kg/km) | Tensile Strength | Crush Resistance | Bending Radius |

| Long/Short Term | Long/Short Term | Static/ Dynamic | ||||

| N | N/100mm | mm | ||||

| GYFTA | 2~6 | 10.3 | 93 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 8~12 | 10.3 | 92 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 14~18 | 10.3 | 92 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 20~24 | 10.3 | 91 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 26~30 | 10.3 | 90 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 32~36 | 10.3 | 89 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 38~48 | 10.7 | 98 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 50~60 | 10.7 | 97 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 62~72 | 10.7 | 96 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 74~84 | 11.5 | 107 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 86~96 | 12.1 | 119 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 98~108 | 12.8 | 133 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 110~120 | 13.5 | 149 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 122~132 | 14.2 | 164 | 600/1500 | 300/1000 | 10D/20D |

| GYFTA | 134~144 | 14.9 | 179 | 600/1500 | 300/1000 | 10D/20D |

| Temperature Range | ||||||

| Working | -40℃~+70℃ | |||||

| Storage/Transportation | -40℃~+70℃ | |||||

| Installation | -20℃~+60℃ | |||||

| Product Features & Application | ||||||

| Characteristics: | ||||||

| 1. Good mechanical and temperature performance | ||||||

| 2. High strength loose tube that is hydrolysis resistant | ||||||

| 3. Special tube filling compound ensure a critical protection of fiber | ||||||

| 4. Specially designed compact structure is good at preventing loose tubes from shrinking | ||||||

| 5. The following measures are taken to ensure the cable watertight: | ||||||

| ....Single Fiber Reinforced Plastic as the central strength member | ||||||

| ....Loose tube filling compound | ||||||

| ....100% cable core filling | ||||||

| ....APL moisture barrier | ||||||

| Standards: | ||||||

| GYFTA cable complies with Standard YD/T 901-2001as well as IEC 60794-1. | ||||||

| Fiber Details | ||||||

| Fiber type | G.652D | G655 | G657A.2 | OM2 | OM3 | |

| MFD @1310nm | 9.2±0.4μm | 1550nm: 9.6±0.5μm | 8.8±0.4μm | 50±2.5um | 50±2.5um | |

| OD of Cladding | 128.0±0.7μm | 125.0±0.7μm | 125.0±0.7μm | 125±1.0um | 125±2.0um | |

| Concentricity error | ≤0.5μm | ≤0.6μm | ≤0.5μm | ≤1.5um | ≤1.5um | |

| Non-circularity of cladding | ≤ 0.7% | ≤ 1.0% | ≤ 0.7% | ≤ 2.0% | ≤ 2.0% | |

| Cutoff wavelength | Λcc ≤1260 nm | Λcc ≤1450 nm | Λcc ≤1260 nm |

| | |

| Attenuation coefficient | ||||||

| 1310nm | ≤0.34dB/km | 1550nm : ≤0.22 dB/km | ≤0.35 dB/km | 850nm: ≤ 2.5dB/km | 850nm: ≤ 2.5dB/km | |

| 1550nm | ≤0.20 dB/km | 1625nm: ≤0.24 dB/km | ≤0.22 dB/km | 1300nm: ≤ 0.7dB/km | 1300nm: ≤ 0.7dB/km | |

| Dispersion coefficient | 1285-1340nm≤-3.0 ~ 3.0 ps/nm².km | 1530-1565nm≤2.0-6.0ps/nm².km |

|

|

| |

| 1550nm≤18ps/nm².km | 1565-1625nm≤4.5-11.2ps/nm².km |

|

|

| ||

| Zero-dispersion wavelength | 1312±10 nm | ≤1520nm | 1300nm-1324nm | 1295-1320 nm | 1295-1320 nm | |

| Zero-dispersion point slope | ≤0.092ps/nm2.km | ≤0.084ps/nm2.km | ≤0.092ps/nm2.km | 1300-1320nm: ≤ 0.11 ps/(nm2.km) | ≤0.11 ps/(nm2.km) | |

| PMDQ | PMD Q*≤0.2ps/km1/2 | PMD Q*≤0.2ps/km1/2 | PMD Q*≤0.2ps/km1/2 |

|

| |

| OD of coating layer | 245±5μm | 245±7μm | 245±5μm | 245±10um | 245±10um | |

| Screen tension | 100kpsi(0.7Gpa) | 100kpsi(0.7Gpa) | 0.69MPa | 100kpsi 0.7GPa | 100kpsi 0.7GPa | |

| PACKAGE AND MARK | ||||||

| 4.1 PACKAGE: Not allowed two length units of cable in one drum, two ends should be sealed,. Two ends should be packed inside drum. | ||||||

| 4.2 MARK: length, brand drum mark: manufacturer, cable category, No. of drum, length, GW. direction of rotation, manufacturing date. | ||||||

| 4.3 Package Length: by order | ||||||

LASUN

LASUN