| GJBFJV Fan-out FO 6~48 Core (LX2012) | ||||||||||||

| Configuration & Physical characters | ||||||||||||

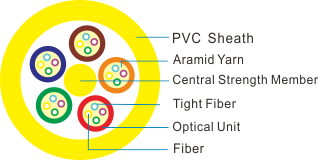

| The fibers, 125μm, are positioned in a buffer tube made of a high modulus plastic sheathed with PVC/LSZH material for cable with high fiber count, locates in the center of core as a FRP strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The poly ester tape barrier is longitudinally applied over the cable core, which is filled with the filling compound to protect it from water ingress. The cable is completed with a PVC/LSZH/PE sheath. | | |||||||||||

| Product Specification | ||||||||||||

| Cable Type | Fiber Count | Unit | Cable Diameter(mm) | Cable Weight(kg/km) | Tensile Strength | Crush Resistance | Bending Radius | |||||

| Long/Short Term | Long/Short Term | Static/ Dynamic | ||||||||||

|

|

|

|

| PVC | LSZH | N | N/100mm | mm | ||||

| GJBFJH(V) | 36 | 6 | 15.7 | 209 | 215 | 600/1500 | 300/1000 | 15D/20D | ||||

| GJBFJH(V) | 48 | 8 | 18.5 | 285 | 292 | 600/1500 | 300/1000 | 15D/20D | ||||

| Temperature Range | ||||||||||||

| Working | -20℃~+60℃ | |||||||||||

| Storage/Transportation | -20℃~+60℃ | |||||||||||

| Installation | -10℃~+50℃ | |||||||||||

| Product Features & Application | ||||||||||||

| Product Property | ||||||||||||

| 1. Aramid fiber in tube unit and strength member design enhance the high strength performance, flexible and non-factice solution make it easy for installation and connection. | ||||||||||||

| 2. Tight-buffered fiber core with independent strengthened unit and jacket to protect the damage from outside | ||||||||||||

| 3. Fiber not bundled, SZ stranded technology, Rip cord design make cable easily ripped and assembled to save installing time and cost | ||||||||||||

| 4. Embedded jacket structure stop movement of stranded unit, which makes cable core structure more stable, with high mechanical strength | ||||||||||||

| 5. LSZH PVC jacket design with non-flammability and self-quenched characteristicsfit for installation in data room, cable shaft, wall inside indoor circumstance | ||||||||||||

| 6. LSZH PE Sheath, uvioresistant,waterproof,mould proof, cracking resistent against environment stress; no acid gas released to corrode data room, fit for outdoor environment and high flame retardant grade need indoor environment , | ||||||||||||

| 7. Tubes color designed according to category of fiber, comply with TIA/EIA-B chromatography | ||||||||||||

| 8. Cable information and length printed on outside jacket | ||||||||||||

| 9. Customized service on fiber counts and other specification. | ||||||||||||

| Application | ||||||||||||

| 1. Indoor horizontal cabling,vertical wiring in building structure and LAN web. | ||||||||||||

| 2. Standard fiber for connectors installation directly, used between equipments. | ||||||||||||

| 3. As end cable of backbone network, can connect from outdoor to indoor directly without joint box, thunder isolated,enhances the reliability of system. | ||||||||||||

| Fiber Details | ||||||||||||

| Fiber type | G.652D | G655 | G657A.2 | OM2 | OM3 | |||||||

| MFD @1310nm | 9.2±0.4μm | 1550nm: 9.6±0.5μm | 8.8±0.4μm | 50±2.5um | 50±2.5um | |||||||

| OD of Cladding | 128.0±0.7μm | 125.0±0.7μm | 125.0±0.7μm | 125±1.0um | 125±2.0um | |||||||

| Concentricity error | ≤0.5μm | ≤0.6μm | ≤0.5μm | ≤1.5um | ≤1.5um | |||||||

| Non-circularity of cladding | ≤ 0.7% | ≤ 1.0% | ≤ 0.7% | ≤ 2.0% | ≤ 2.0% | |||||||

| Cutoff wavelength | Λcc ≤1260 nm | Λcc ≤1450 nm | Λcc ≤1260 nm |

| | |||||||

| Attenuation coefficient | ||||||||||||

| 1310nm | ≤0.34 dB/km | 1550nm: ≤ 0.32 dB/km | ≤0.35 dB/km | 850nm: ≤ 2.5dB/km | 850nm: ≤ 2.5dB/km | |||||||

| 1550nm | ≤0.20 dB/km | 1625nm: ≤0.24 dB/km | ≤0.22 dB/km | 1300nm: ≤ 0.7dB/km | 1300nm: ≤ 0.7dB/km | |||||||

| Dispersion coefficient | 1285-1340nm≤-3.0~3.0ps/nm².km | 1530-1565nm≤2.0-6.0ps/nm².km |

|

|

| |||||||

| 1550nm≤18ps/nm².km | 1565-1625nm≤4.5-11.2ps/nm².km |

|

|

| ||||||||

| Zero-dispersion wavelength | 1312nm±10nm | ≤1520nm | 1300nm-1324nm | 1295-1300 nm | 1295-1300 nm | |||||||

| Zero-dispersion point slope | ≤0.092ps/nm2.km | ≤0.084ps/nm2.km | ≤0.092ps/nm2.km | 1300-1320nm:≤ 0.11 ps/(nm2.km) | ≤0.11 ps/(nm2.km) | |||||||

| PMDQ | PMD Q*≤0.2ps/km1/2 | PMD Q*≤0.2ps/km1/2 | PMD Q*≤0.2ps/km1/2 |

|

| |||||||

| OD of coating layer | 245±5μm | 245±7μm | 245±5μm | 250±10um | 250±10um | |||||||

| Screen tension | 100kpsi(0.7Gpa) | 100kpsi(0.7Gpa) | 0.69MPa | 100kpsi(0.7GPa) | 100kpsi(0.7GPa) | |||||||

| PACKAGE AND MARK | ||||||||||||

| 4.1 PACKAGE: Not allowed two length units of cable in one drum, two ends should be sealed,. Two ends should be packed inside drum. | ||||||||||||

| 4.2 MARK: length, brand drum mark: manufacturer, cable category, No. of drum, length, GW. direction of rotation, manufacturing date. | ||||||||||||

| 4.3 Package Length: by order | ||||||||||||

LASUN

LASUN